In the metal processing, aluminum cutting, and woodworking board industries, tungsten carbide circular saw blades have been widely used as efficient and wear-resistant cutting tools. When users purchase and use tungsten carbide circular saw blades, one of the most concerned issues is: How long can tungsten carbide circular saw blades last?

This is not only related to production efficiency and processing quality, but also directly affects the operating costs of the enterprise. This article will start from the material characteristics of tungsten carbide circular saw blades, deeply analyze the determining factors of its service life, and provide a series of practical and feasible life extension suggestions to help users improve economic benefits and processing efficiency.

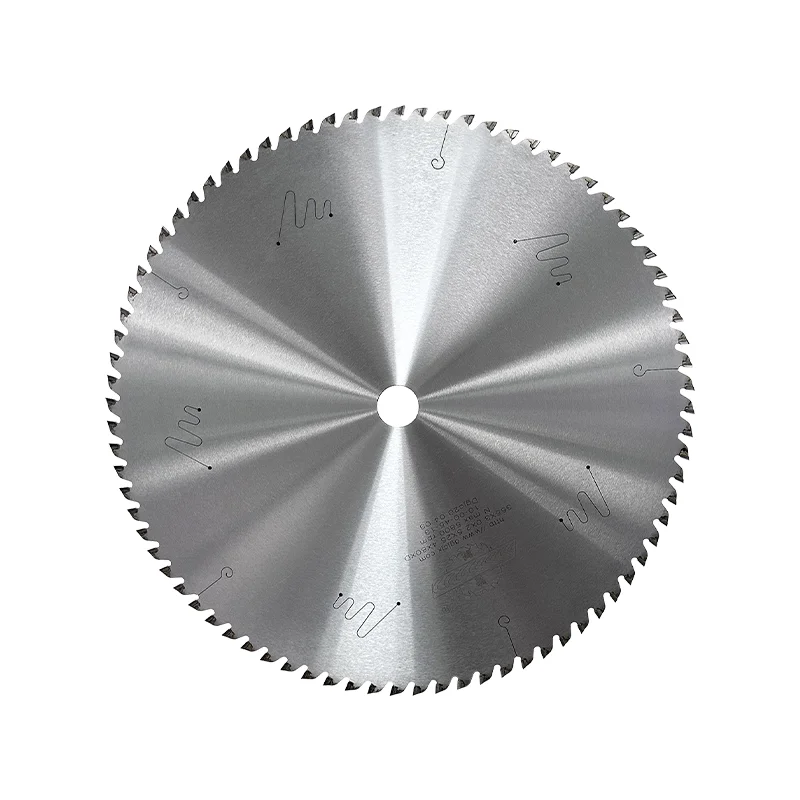

1. What is a tungsten carbide circular saw blade? Why is life longer than that of ordinary saw blades?

Tungsten carbide circular saw blades, also known as carbide circular saw blades, usually use carbide materials (such as YG8, YG6X, etc.) made of metal elements such as tungsten (W) and carbon (C). Tungsten steel is characterized by high hardness, high wear resistance, high temperature resistance, and strong impact resistance. Therefore, tungsten steel saw blades have significantly improved life compared to high-speed steel (HSS) or carbon steel saw blades.

Generally speaking, the cutting life of tungsten carbide circular saw blades is 3 to 10 times that of ordinary steel saw blades, or even higher. Depending on the application environment, a high-quality tungsten carbide circular saw blade can complete thousands or even tens of thousands of cutting tasks.

2. Factors affecting the service life of tungsten carbide circular saw blades

Although tungsten steel saw blades have strong wear resistance, their lifespan is not constant in actual use, but is affected by a combination of factors:

2.1 Type of cut material

The degree of wear on saw blades varies significantly when cutting different materials:

Aluminum and plastic: relatively soft, less wear, and longer service life;

Hard metals such as stainless steel, copper, and alloy steel: wear quickly and have a relatively short life;

Wood (especially hardwood and plywood): Although it has a low density, it sometimes contains impurities such as sand and glue, which can also aggravate wear.

2.2 Saw blade quality and manufacturing process

High-quality tungsten carbide circular saw blades excel in the following aspects:

The blade head is made of micro-particle tungsten steel, which has high hardness and strong crack resistance;

The welding process is stable and it is not easy to lose teeth;

The tooth shape design is reasonable and the cutting is smoother;

The saw plate material is rigid and not easy to deform during cutting.

If the quality of the saw blade is not up to standard, even if the material is marked as tungsten steel, problems such as early wear and tooth collapse may occur, which seriously affect the service life.

2.3 Equipment speed and feed speed

Irrational use parameters will significantly affect the life of the saw blade:

Too fast speed will cause the blade to overheat and anneal;

Too slow speed may cause unclean cutting and dragging;

Too fast feed speed is easy to cause tooth collapse;

Too slow feed speed affects processing efficiency.

Usually, the reasonable speed and feed speed should be adjusted according to the material type and saw blade diameter to ensure smooth processing and maximize life.

2.4 Cooling and lubrication conditions

When cutting metal or hard materials, the use of coolant or lubricant can effectively reduce the cutting temperature, reduce thermal expansion, and delay the wear of the blade. If dry cutting is performed frequently, the saw blade will easily overheat, causing the blade to crack or fall off, thus being scrapped in advance.

2.5 Operating habits and maintenance frequency

Bad operating habits (such as forced cutting, repeated retraction) or long-term cleaning and maintenance of the saw blade will accelerate wear. For example:

Not removing the accumulated chips on the blade will cause the blade to become blunt;

Not cleaning the saw board for a long time may cause increased deflection and unstable cutting;

Not checking the saw blade regularly for eccentricity or cracks may easily cause accidents and damage.

3. How to extend the service life of tungsten carbide circular saw blades?

In order to obtain the maximum economic benefit, the following suggestions can effectively extend the life of the saw blade:

3.1 Choose the appropriate saw blade specifications

According to the processing material, thickness, and incision requirements, select the appropriate number of teeth, tooth shape, outer diameter and aperture;

Try to use professional saw blades (such as special blades for aluminum, steel, and wood) instead of general-purpose ones.

3.2 Use with cooling and lubrication system

It is recommended to use water cooling or oil cooling equipment, especially when cutting metal materials;

Using spray-type micro-lubrication (MQL) also has a good cooling and wear reduction effect.

3.3 Reasonable setting of sawing parameters

Control the balance between rotation speed and feed speed to avoid violent vibration;

Avoid sudden feeding and heavy pressure cutting.

3.4 Regular maintenance and cleaning

Clean the surface of the saw blade after work every day;

Regularly check whether the blade is blunt or defective, and perform secondary grinding when necessary;

When the saw blade is not in use, it should be hung and stored to avoid bumps.

3.5 Avoid misoperation

Operators should receive professional training to ensure smooth feeding and correct clamping;

Avoid stress shock caused by sudden power failure or emergency stop during cutting.

4. Analysis of common misunderstandings about the life of tungsten carbide circular saw blades

Misunderstanding 1: The more expensive the tungsten steel saw blade, the longer its life

Price is not the only criterion for judging the life of the saw blade. Brand reputation, actual adaptability, processing method, and saw machine performance may affect the final life.

Myth 2: Dry cutting is easier and does not require cooling

Dry cutting is possible for some woodworking materials, but for metal materials, lack of cooling can easily cause the blade to burn or crack, which shortens its life.

Myth 3: Replace it if it is not sharp, without considering grinding

In fact, tungsten steel blades can be grinded and reused many times. As long as the blade is not cracked, it can be re-grinded with professional equipment to greatly extend its service life.

As a high-performance cutting tool, tungsten carbide circular saw blades play an important role in the processing field. Its service life depends not only on the quality of the product itself, but also on the user's operation method and maintenance frequency.

Through scientific selection, reasonable operation and regular maintenance, even in high-intensity cutting scenarios, a tungsten steel saw blade can be used to its maximum efficiency, and its service life can reach or even exceed expectations. For corporate users, this not only means reducing the frequency of purchases, but also means the simultaneous improvement of processing stability and profit margins.

If you need to learn about the selection suggestions for tungsten carbide circular saw blades suitable for different materials, or customize high-performance saw blades that meet special processing needs, please contact us: professional suppliers for more technical support.

www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd.