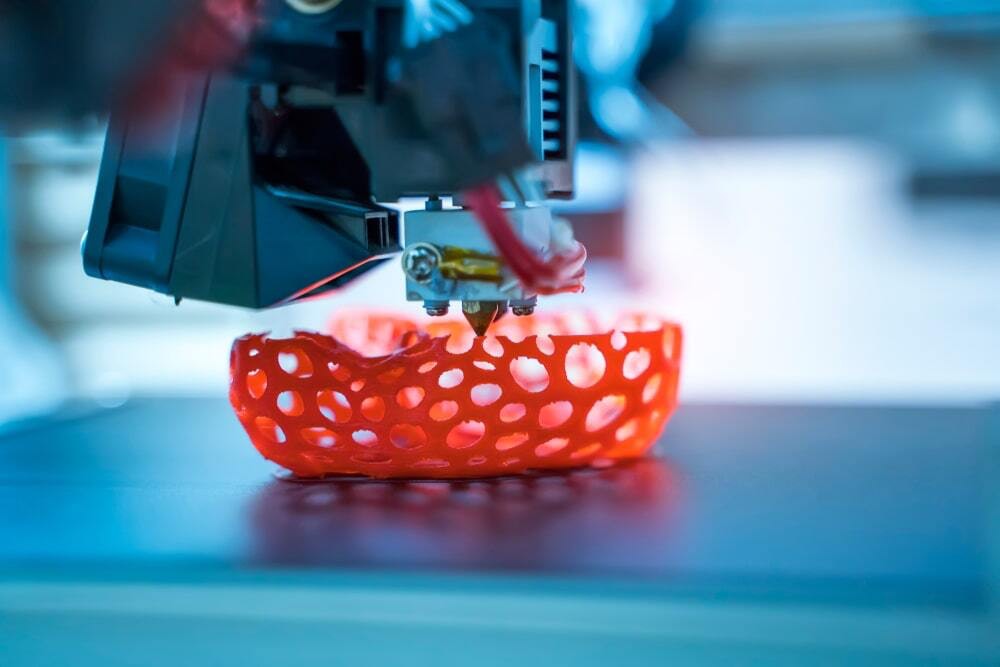

3D printing, also known as additive manufacturing, has revolutionized the production of various items, from intricate jewelry to complex architectural models. One of the most common materials used in this process is plastic. However, a frequently asked question is, How long does 3D printing plastic last? This article aims to provide an in-depth analysis of this topic, considering various factors that influence the lifespan of 3D printed plastic objects.

Factors Influencing the Lifespan of 3D Printed Plastic

- Type of Plastic: The longevity of a 3D printed object largely depends on the type of plastic used. For instance, ABS (Acrylonitrile Butadiene Styrene) is known for its durability and strength, making it suitable for long-lasting applications. On the other hand, PLA (Polylactic Acid) is biodegradable and may not last as long as ABS.

- Printing Process: The quality of the 3D printing process also impacts the lifespan of the printed object. A well-calibrated printer that accurately follows the design blueprint will produce a more durable object.

- Post-Processing: Post-processing techniques like annealing can enhance the durability of 3D printed plastic. Annealing involves heating the object in a controlled environment to reduce internal stresses and improve its mechanical properties.

- Environmental Conditions: Exposure to sunlight, moisture, and extreme temperatures can degrade plastic over time. Therefore, 3D printed objects used outdoors or in harsh environments may not last as long as those used indoors.

Estimating the Lifespan of 3D Printed Plastic

Given the factors mentioned above, it's challenging to provide a one-size-fits-all answer to the question, How long does 3D printing plastic last? However, under normal indoor conditions, a 3D printed object made from ABS or a similar durable plastic, properly printed and post-processed, can last several years, if not decades.

It's worth noting that while the physical object may remain intact, its functional lifespan may be shorter. For example, a 3D printed gear may wear out with use, or a 3D printed phone case may become obsolete when the phone model it was designed for is no longer in use.

Conclusion

In conclusion, the lifespan of 3D printed plastic is influenced by a multitude of factors, including the type of plastic, the printing process, post-processing techniques, and environmental conditions. While it's difficult to provide a definitive lifespan, with proper care and under favorable conditions, 3D printed plastic objects can serve their purpose for many years.

As 3D printing technology continues to evolve, we can expect improvements in the durability and longevity of 3D printed plastic. For now, understanding these factors can help users make informed decisions about the use and care of their 3D printed objects.