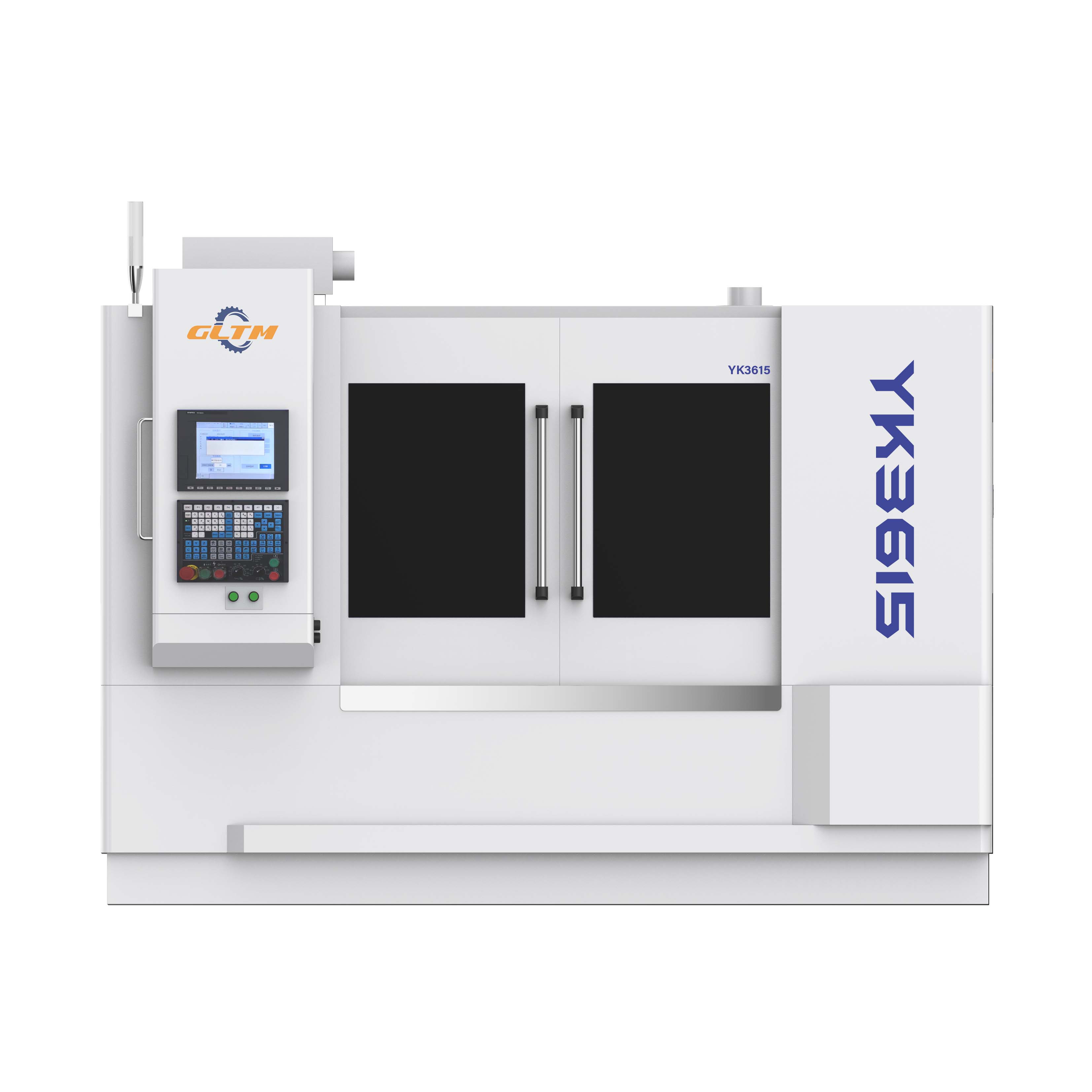

In the world of modern gear and shaft production, precision, efficiency, and reliability are non-negotiable. As industries such as automotive, motorcycle, robotics, and industrial machinery demand higher manufacturing standards, investing in the right equipment becomes essential. Among the many advanced gear-cutting machines available, the YK3615 Spline Shaft Milling Machine stands out as a benchmark in high-precision spline manufacturing.

Designed and manufactured by GLT Machinery (GLTM/GLT)—a leading CNC gear machinery manufacturer in China—the YK3615 exemplifies the company’s core values of rigid structure, high efficiency, and long-term reliability. With a focus on CNC gear hobbing and gear shaping technologies, GLT has successfully delivered complete gear machining solutions to clients in the automotive, reducer, timing pulley, pump, and motorcycle industries.

Here’s a closer look at the top features that make the YK3615 an ideal solution for precision-driven manufacturing environments.

1. High Rigidity and Structural Stability

The YK3615 is engineered with a heavy-duty cast iron bed and high-strength frame to ensure structural rigidity and vibration resistance. This stable foundation plays a vital role in maintaining dimensional accuracy during high-speed cutting, especially when producing complex splines or large batch runs.

By minimizing deflection and mechanical error, GLT’s design helps users achieve tight tolerances and exceptional surface finishes on every shaft.

2. Advanced CNC Control System

Equipped with a state-of-the-art CNC control system, the YK3615 offers automated and programmable control of all key machining parameters. This allows operators to achieve:

-

Precise feed rates

-

Multi-axis interpolation

-

Real-time adjustments

-

Easy integration into automated production lines

GLT Machinery configures the YK3615 with internationally recognized CNC controllers that support fast setup, intuitive operation, and compatibility with a wide range of part geometries.

3. Wide Range of Spline Processing Capabilities

Whether you’re producing involute splines, straight-sided splines, or special profiles, the YK3615 supports flexible programming and tool change options. This makes it suitable for:

-

Automotive drive shafts

-

Motorcycle transmission components

-

Reducer gears

-

Synchronous belt pulleys

-

Pump shafts and rotor hubs

Manufacturers can switch seamlessly between different workpieces without needing a separate machine for each part type—increasing productivity and reducing capital investment.

4. High-Efficiency Machining

The YK3615 is built for speed without sacrificing precision. It uses high-performance servo motors and efficient tool paths to reduce cycle time while maintaining consistent accuracy. Ideal for mass production environments, this milling machine can handle long runs with minimal operator intervention.

Combined with GLT’s high-speed hobbing expertise, the machine enables cost-effective large-volume production for industries demanding rapid turnaround.

5. User-Friendly Interface and Maintenance

Despite its advanced capabilities, the YK3615 is designed with operator convenience in mind. It features:

-

An ergonomic control panel

-

Easy tool mounting and workpiece loading

-

Simplified diagnostics and maintenance access

-

Safety enclosures and automatic chip removal systems

These features help minimize training time, reduce errors, and ensure a safe, clean, and efficient working environment.

6. Customizable and Scalable

GLT Machinery understands that every customer’s needs are different. That’s why the YK3615 can be customized with optional accessories and configurations, such as:

-

Tailstocks for longer shafts

-

Hydraulic fixtures

-

Automatic loading systems

-

Coolant and filtration systems

This flexibility makes the machine scalable for both standalone workstations and fully automated production lines, helping manufacturers adapt to evolving market demands.

Why Choose GLT Machinery?

With years of experience in gear machining technology, GLT Machinery (GLTM/GLT) is recognized for delivering high-speed, high-precision, and high-reliability CNC gear-cutting solutions. The company integrates CAD, CAM, and advanced control systems to develop innovative machines tailored to customer requirements.

From gear hobbing to spline milling, GLT supports manufacturers in automotive, motorcycle, industrial drive, and pump sectors with machines that deliver consistent performance, low maintenance, and long-term value.

Final Thoughts

The YK3615 Spline Shaft Milling Machine is more than just a piece of equipment—it’s a competitive advantage for manufacturers who demand precision, speed, and reliability. With its robust design, intelligent control, and versatile application range, the YK3615 is an ideal choice for modern machining operations that can’t afford to compromise on quality.

Backed by the engineering excellence of GLT Machinery, this machine helps future-focused factories meet today’s toughest spline production challenges—and prepare for tomorrow’s opportunities.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd.