In today's rapidly advancing technological landscape, understanding the differences between mechanical and solid-state technologies is crucial. Both play pivotal roles in various industries, but their underlying principles and applications differ significantly. This article aims to delve into the intricacies of these two technologies, highlighting their unique characteristics, advantages, and applications.

- Definition and Core Principles:

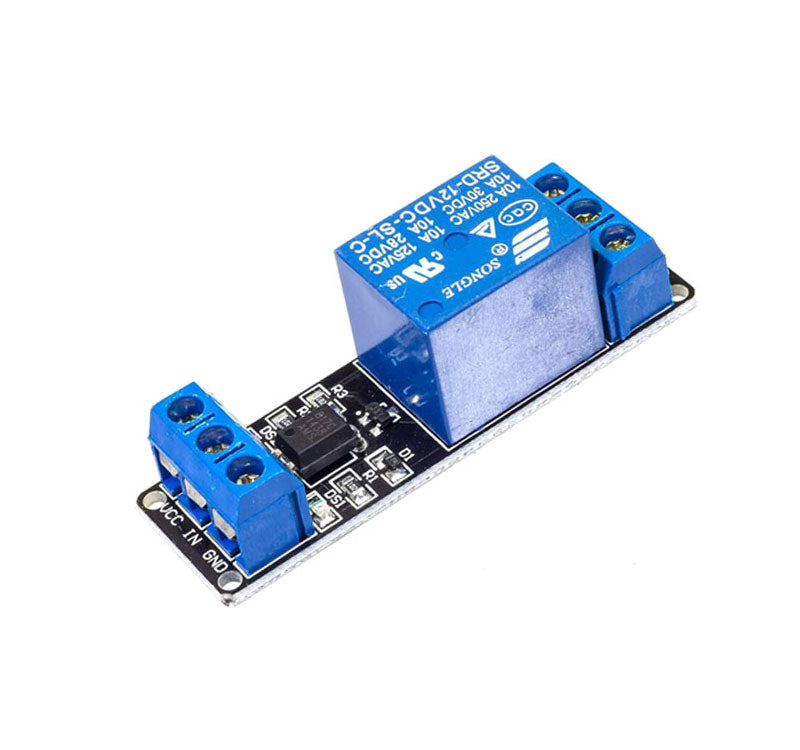

Mechanical technology relies on the physical movement and interaction of mechanical components, such as gears, levers, and pulleys, to perform tasks. On the other hand, solid-state technology utilizes the properties of solid materials, such as semiconductors, to manipulate electrical signals and achieve desired outcomes. - Energy Efficiency and Power Consumption:

One key distinction between mechanical and solid-state technologies lies in their energy efficiency and power consumption. Solid-state devices, such as transistors and integrated circuits, are known for their low power consumption and high energy efficiency. In contrast, mechanical systems often require more energy to operate efficiently, as they involve physical movement and friction. - Reliability and Durability:

Solid-state technologies have gained popularity due to their inherent reliability and durability. With no moving parts, they are less prone to wear and tear, making them suitable for long-term use. Mechanical systems, while robust in their own right, are subject to mechanical failures and require regular maintenance to ensure optimal performance. - Speed and Precision:

Solid-state technologies excel in terms of speed and precision. Electronic components can switch on and off rapidly, enabling high-speed data processing and communication. Additionally, solid-state devices offer precise control over electrical signals, making them ideal for applications that demand accuracy, such as medical devices and scientific instruments. Mechanical systems, although capable of achieving high speeds, may have limitations in terms of precision due to factors like mechanical tolerances. - Applications:

Mechanical technology finds extensive use in industries such as automotive, aerospace, and manufacturing, where physical movement and force transmission are essential. It powers engines, turbines, and mechanical systems that drive various machinery. Solid-state technology, on the other hand, dominates the electronics industry, enabling the development of computers, smartphones, renewable energy systems, and advanced medical devices.

Conclusion:

Understanding the differences between mechanical and solid-state technologies is crucial for professionals across industries. While mechanical systems excel in physical force transmission, solid-state technologies offer energy efficiency, reliability, speed, and precision. By recognizing the unique characteristics and applications of each, engineers and innovators can make informed decisions when selecting the appropriate technology for their specific needs.