In today’s paddle market, many designs look good on paper.

Higher spin numbers. New surface names. More foam, more layers, more claims.

From the manufacturing side, we see something different.

We see how many of those paddles cannot survive production, or cannot stay consistent once volume increases. So when we talk about a paddle being “qualified,” we are not talking about marketing performance. We are talking about whether it can actually be made, repeated, and trusted.

This is how we judge it at AMA Industry.

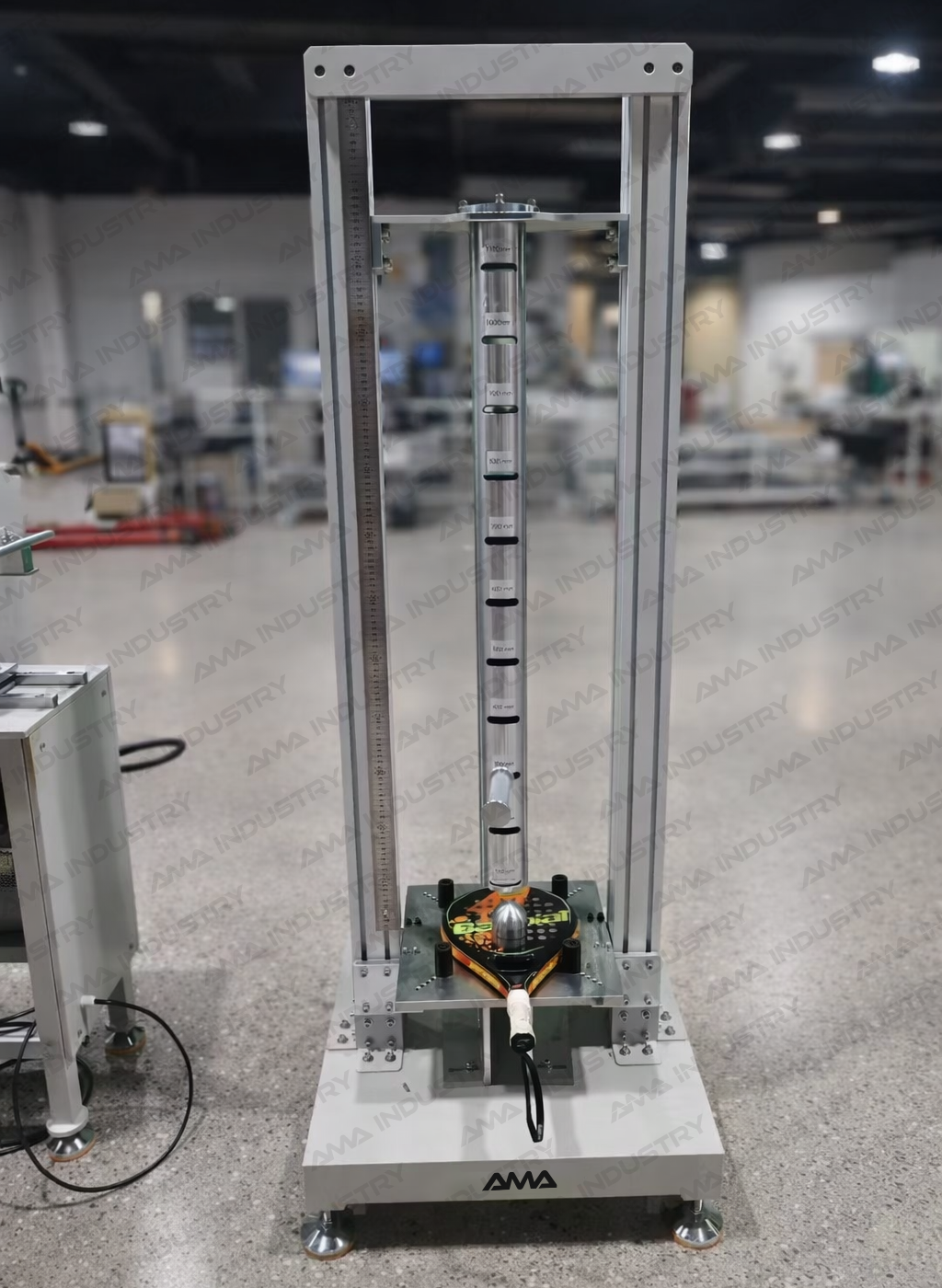

1. Impact & Rebound Testing: When “Good Feel” Is Not Enough

We often receive samples that feel great in hand.

Soft touch. Fast rebound. But once they enter impact testing, problems appear.

In the impact and rebound test, the paddle face is repeatedly struck under controlled force. What we look for is not maximum bounce—but how stable the response remains over time.

A common issue we see in the current market:

● Strong rebound in the first few hits

● Noticeable drop after repeated impacts

When that happens, it usually means the internal structure is over-tuned for feel but under-supported for production durability.

From a factory perspective, this is a red flag. A paddle that changes behavior quickly cannot be released for mass production.

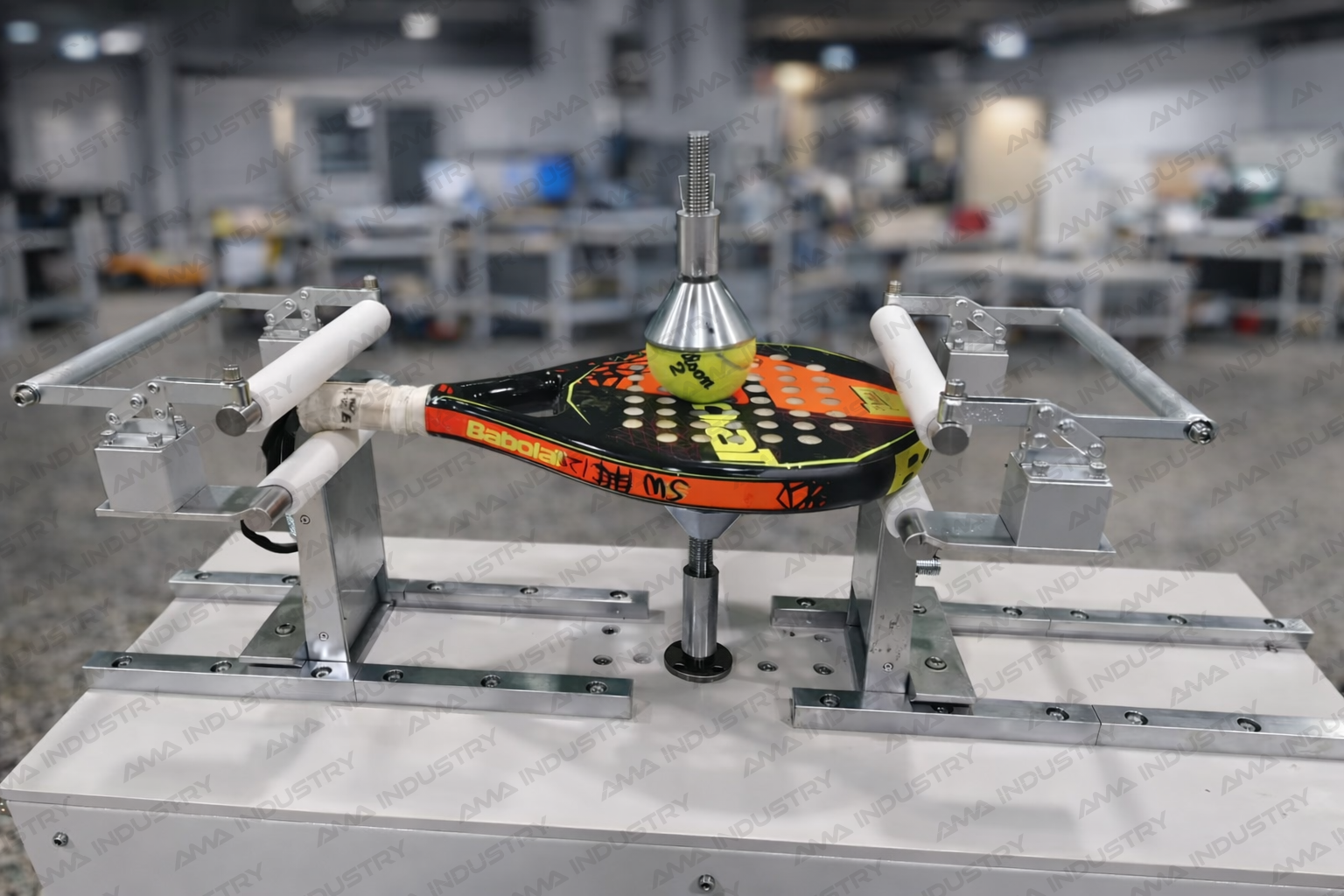

2. Fatigue Testing: Where Many Designs Fail Quietly

Fatigue testing is where many “high-performance” designs disappear.

In this test, the paddle is bent repeatedly to simulate long-term play. Not hundreds of hits—but thousands.

We have seen paddles that:

● Pass initial impact tests

● Look perfect visually

● But slowly lose stiffness during fatigue cycles

This is especially common in today’s market, where softer cores and complex foam structures are widely used.

For us, durability is not about breaking or not breaking. It is about performance retention.

If the structure cannot maintain its behavior over time, we do not consider it qualified—no matter how advanced the materials sound.

3. High-Speed Impact Simulation: Testing the Real-World Limits

Players don’t always hit clean shots.

They hit off-center. They swing harder than expected. They play faster than design assumptions.

High-speed impact testing helps us see how a paddle behaves under these extreme conditions.

What we are watching for:

● Sudden vibration spikes

● Abnormal deformation

● Structural instability at high energy input

In recent years, as paddle power has increased across the market, this test has become more important than ever.

A Pro-level factory must ensure that performance gains do not come at the cost of structural safety.

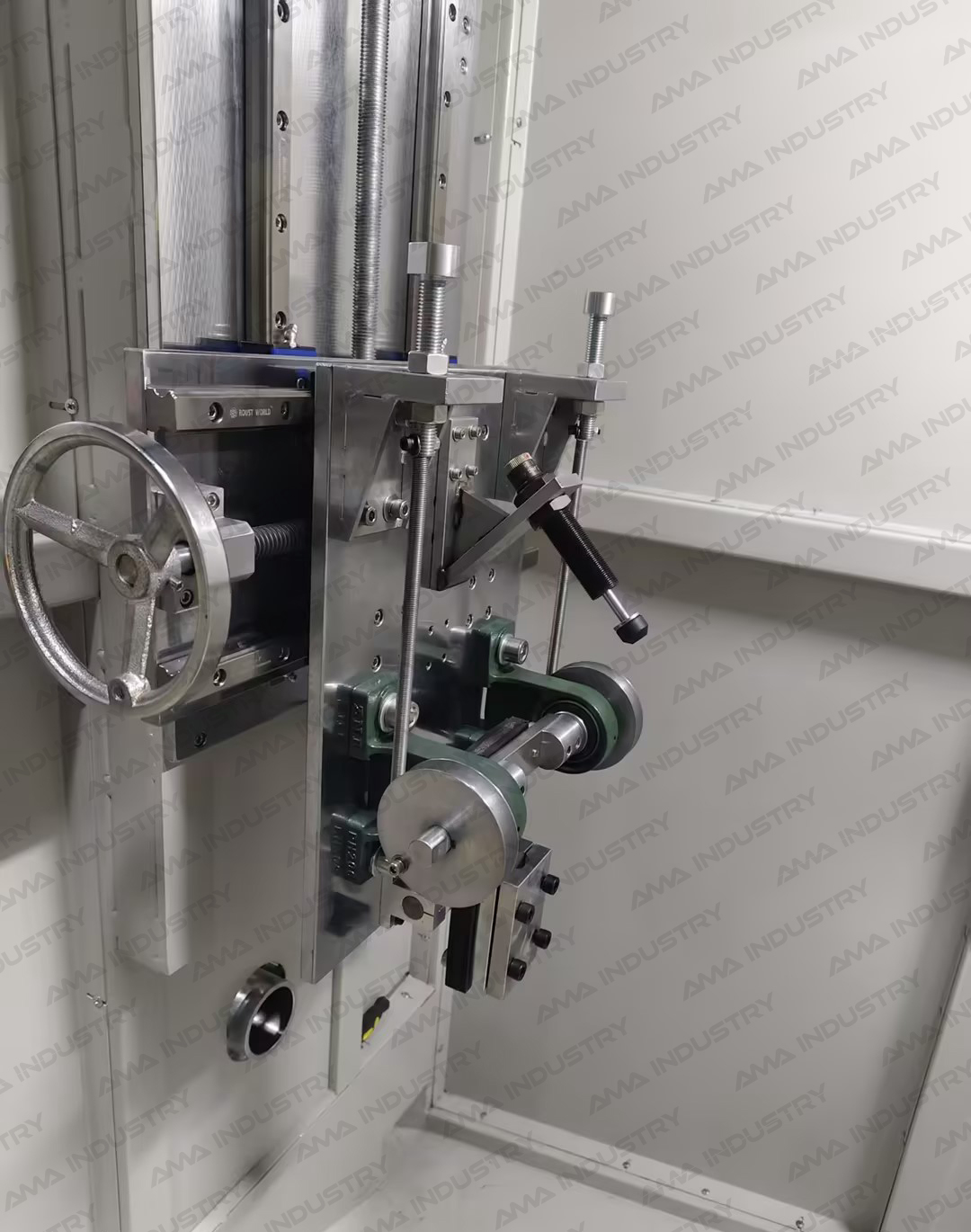

4. Universal Mechanical Testing: Turning Design Into a Product

This is the least visible test—but often the most decisive.

Using universal mechanical testing, we measure:

● Tensile strength

● Compression resistance

● Structural limits

These numbers help us answer practical manufacturing questions:

● Can this design handle production variation?

● Where is the failure threshold?

● How tight can we control consistency across batches?

Many designs work as samples. Fewer designs work as products.

This test tells us the difference.

What “Qualified” Really Means in a Pro Factory

At AMA Industry, being a Pro-level racket manufacturer means saying “no” more often than “yes.”

A qualified paddle is not the one with the most features. It is the one that:

● Can be produced consistently

● Can survive long-term use

● Can keep its performance within tolerance

● Can support a brand over time

This is how we work. This is how we judge.

Not from the market. But from the manufacturing side.

www.amasport.com

AMA SPORT