In today’s fast-paced industrial landscape, precision, efficiency, and reliability are more critical than ever—especially in CNC machining and automated manufacturing environments. At the heart of many of these advanced systems lies a highly specialized component: the RV gearbox.

As a key player in transmission technology, Yijiaang Automation Technology Co., Ltd. is deeply committed to the development, application, sales, and technical services surrounding advanced motion control components, including high-performance RV gearboxes. In this article, we’ll explore what RV gearboxes are, how they function, and why they are indispensable in CNC and automated production systems.

What is an RV Gearbox?

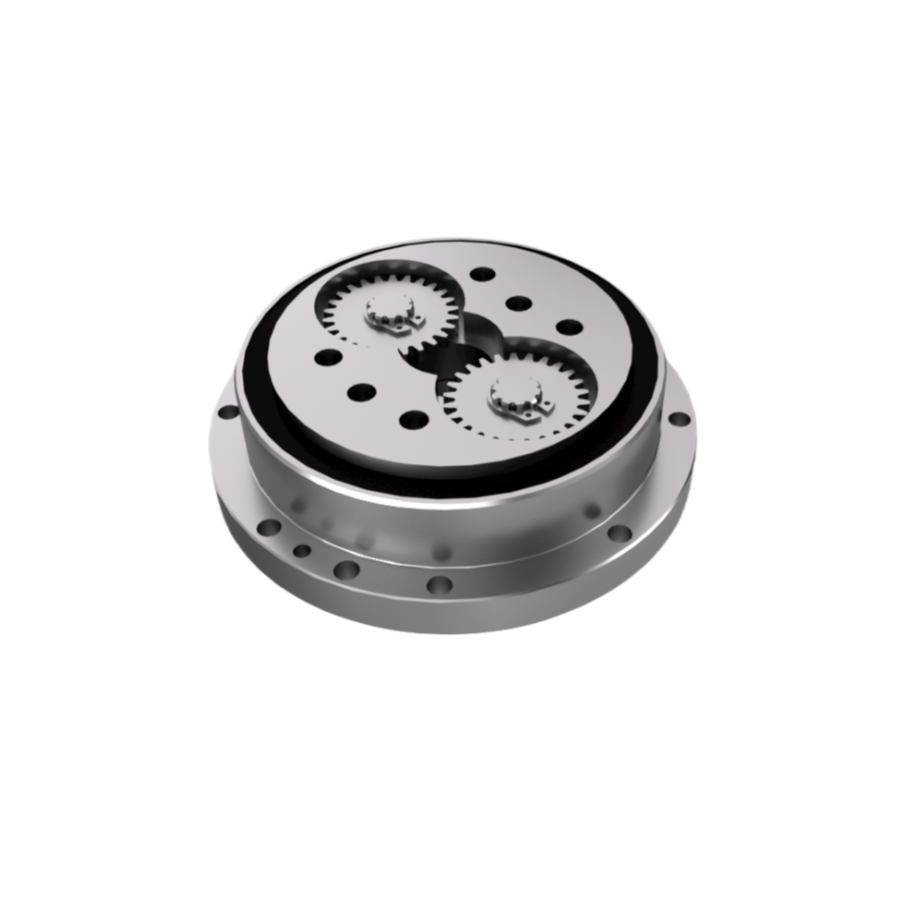

RV gearboxes (short for "Rotary Vector" or sometimes referred to as "Cycloidal gear reducers") are compact, high-precision reducers designed to transmit motion with low backlash and high torque in a compact footprint. Unlike conventional gear systems, RV reducers use a cycloidal disc mechanism to distribute load across multiple points, ensuring:

High torque output

Exceptional positioning accuracy

High shock-load tolerance

Minimal backlash (<1 arc minute in high-end models)

These characteristics make them ideal for robotics, CNC machines, and other automated applications that demand both accuracy and durability.

The Importance of RV Gearboxes in CNC Machining

CNC (Computer Numerical Control) machining demands high precision in every axis movement. Even a slight deviation can ruin an entire part or slow down production. Here’s where RV gearboxes prove vital:

1. Ultra-Precision Motion Control

The low backlash in RV gearboxes ensures that rotary movements are precise, which is essential for detailed and intricate machining tasks. In high-speed CNC applications, even micrometer-level accuracy counts.

2. Enhanced Load Distribution

The internal cycloidal design allows RV gearboxes to distribute loads more evenly compared to traditional gear types. This enhances performance, reduces wear, and extends operational lifespan.

3. Compact Design for Tight Spaces

Despite their high torque output, RV gearboxes are compact—perfect for CNC machines where space efficiency is crucial.

4. Vibration and Shock Absorption

The mechanical configuration of RV reducers provides excellent resistance to vibration and shock, contributing to smoother operation and longer machine life.

Application of RV Gearboxes in Automated Production Systems

In automated production, robots and gantry systems perform repetitive tasks with high speed and consistency. RV gearboxes play a pivotal role in maintaining operational efficiency and accuracy.

Common Use Cases:

Robotic arms and joints: RV gearboxes provide smooth, precise motion in robotic joints, crucial for tasks like welding, assembly, or material handling.

Automated conveyors and gantries: The ability to transmit high torque without backlash allows for exact positioning and synchronized movement.

Packaging machines: In high-speed environments, RV reducers support seamless mechanical coordination between components.

Pick-and-place systems: In electronics manufacturing, RV gearboxes allow for micro-precision when handling delicate components.

Why Yijiaang’s RV Gearboxes?

As a company specializing in the development and distribution of transmission components, Yijiaang Automation Technology Co., Ltd. delivers RV gearboxes that are:

Engineered for high-performance environments

Customizable to specific CNC or automation needs

Backed by a strong technical support team

Compatible with a wide range of servo motors and controllers

Our focus on innovation, reliability, and customer-centric solutions makes us a trusted partner in smart manufacturing.

Benefits of Choosing the Right RV Gearbox

Choosing a suitable RV gearbox for your CNC or automated system can yield significant benefits:

Improved production accuracy

Higher throughput with fewer errors

Reduced maintenance costs

Longer service life of equipment

Scalability for future automation upgrades

Yijiaang provides not just products, but complete technical consultation to ensure each gearbox matches your application perfectly—whether it's a single-axis robot or a full multi-axis machining center.

Conclusion

RV gearboxes may be compact, but their impact on CNC and automated production is substantial. Their ability to deliver high torque, low backlash, and exceptional reliability makes them essential for modern manufacturing systems.

At Yijiaang Automation Technology Co., Ltd., we are proud to be at the forefront of transmission technology innovation, offering products and solutions that empower industries to move smarter and faster. Whether you're upgrading an existing system or designing a new one, our RV gearboxes—and our team—are ready to help you achieve next-level precision and productivity.

Key Features That Make RV Reducers Ideal for Modern Machinery

www.yijiaangreducers.com

Suzhou Yijiaang Automation Technology Co., Ltd.