Precision machining depends heavily on the performance of cutting tools — and few innovations have improved machining efficiency and quality as profoundly as helical coolant hole carbide rods. These tooling solutions are designed to deliver superior chip evacuation, enhanced cooling, and improved cutting stability, making them ideal for demanding applications across aerospace, automotive, mold making, and general manufacturing. In this article, we’ll explore the key benefits of helical coolant hole carbide rods and how companies like Shanghai Diatooling Co., Ltd. are driving innovation in advanced carbide tooling.

What Are Helical Coolant Hole Carbide Rods?

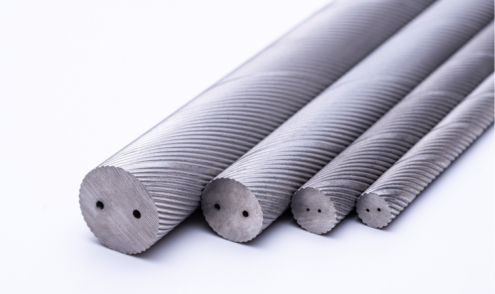

At their core, helical coolant hole carbide rods are solid carbide rods engineered with spiral (helical) coolant channels. These channels allow coolant — delivered under pressure — to reach the cutting edge precisely where heat and chip buildup occur. By combining the strength of carbide with advanced fluid delivery, these rods significantly improve machining dynamics.

Carbide rods are a popular choice for reamers, drills, end mills, and specialized boring tools, but by adding helical coolant holes, manufacturers take performance a step further, particularly in deep holes, challenging materials, and high‑speed machining.

Key Benefits of Helical Coolant Hole Carbide Rods

1. Superior Cooling and Heat Management

One of the most significant advantages of helical coolant holes is their ability to deliver coolant directly to the cutting zone. Traditional external coolant methods often fail to penetrate deep into the cutting interface, especially in blind or deep holes. With helical coolant holes:

-

Heat is dissipated quickly, reducing thermal distortion.

-

Cutting edges stay cooler, preserving sharpness and carbide integrity.

-

Tool life extends significantly, especially in high‑speed and hard material applications.

Efficient heat management also prevents workpiece surface burnishing and reduces the risk of micro‑cracks caused by thermal cycling.

2. Enhanced Chip Evacuation

Effective chip removal is essential for precision machining. When chips accumulate at the cutting edge, they can cause work hardening, tool chipping, or surface imperfections. Helical coolant holes provide:

-

Active chip flushing, helping push chips away from the tool and workpiece.

-

Reduced recutting of chips, which improves surface finish and reduces cutting forces.

-

Lower clogging risk, especially in deep holes or tough alloys.

This benefit is particularly valuable in materials like stainless steel, Inconel, titanium, and other difficult‑to‑machine alloys.

3. Improved Dimensional Accuracy and Surface Finish

Precision components demand tight tolerances and flawless surfaces. Helical coolant hole carbide rods help achieve this by:

-

Maintaining stable cutting temperatures that minimize tool deflection.

-

Reducing vibration and chatter, thanks to better chip flow and cooling.

-

Ensuring consistent material removal rates, which enhances repeatability.

These advantages translate into parts that meet exacting specifications and require less post‑machining finishing work.

4. Increased Tool Life and Lower Production Costs

Longer tool life isn’t just about replacing tools less often — it delivers tangible cost savings:

-

Fewer tool changes, improving machine uptime.

-

Reduced tooling inventory requirements over time.

-

Lower scrap rates, thanks to better surface quality and dimensional control.

When combined with optimized machining strategies, helical coolant hole carbide rods can significantly lower cost per part, especially in high‑volume operations.

Applications Across Industries

Helical coolant hole carbide rods are versatile and beneficial in many sectors:

-

Aerospace: Deep hole drilling and precision milling of high‑strength alloys.

-

Automotive: Efficient machining of engine components and structural parts.

-

Mold & Die: High‑accuracy holemaking and fine finishing.

-

General Manufacturing: Reliable performance in production environments that require consistency and high throughput.

In each context, the ability to deliver coolant precisely and evacuate chips effectively helps maintain process reliability and part quality.

Shanghai Diatooling: Precision Tooling Expertise

Shanghai Diatooling Co., Ltd. is a precision tooling manufacturer focused on advanced carbide tools and solutions. With a passion for innovation and quality, Diatooling specializes in products including CNC tooling, cutting tools, carbide rods, and customized machining solutions for global markets.

Founded with a commitment to high performance and customer satisfaction, the company continuously invests in research and manufacturing capabilities to meet the rising demands of modern machining. Their helical coolant hole carbide rods — engineered with precision geometry and optimized coolant pathways — reflect this commitment to performance, tool life, and process efficiency.

By partnering with manufacturers like Diatooling, production engineers and machining professionals can

https://www.diatooling.com/

Shanghai Diatooling