In today's fast-paced industrial environment, automation has become a cornerstone for enhancing productivity and precision. One such marvel of automation is the automatic flat labeling machine, a device specifically engineered to streamline the process of applying labels onto flat surfaces. This machine has revolutionized industries ranging from food and beverage to pharmaceuticals and consumer goods by ensuring accurate, consistent, and efficient labeling.

Definition of an Automatic Flat Labeling Machine

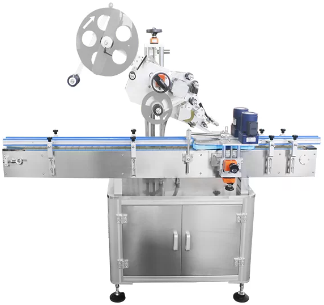

An automatic flat labeling machine is a specialized piece of equipment designed to apply labels automatically onto flat surfaces. It is engineered to handle a variety of products, including bottle caps, packaging bags, and boxes, with unparalleled speed and accuracy. The primary purpose of this machine is to eliminate the inefficiencies and inconsistencies associated with manual labeling, thereby optimizing production workflows and reducing labor costs.

How It Works

Shanghai BEILT Machinery Equipment Co., Ltd. is a manufacturer of automatic flat labeling machine.

The operation of an automatic flat labeling machine is a marvel of engineering simplicity and efficiency. The process begins with the product being fed into the machine, either manually or via an automated conveyor system. Once the product reaches the labeling station, a sensor detects its presence and triggers the labeling mechanism. The label, which is typically stored on a roll, is then dispensed and applied to the flat surface of the product.

Several key components work in tandem to ensure the smooth functioning of the machine. The label dispenser, for instance, is responsible for unwinding the label from the roll and feeding it into the labeling head. The labeling head, equipped with a pressure-sensitive adhesive system, then precisely applies the label onto the product's surface. Advanced models may also feature a cutting mechanism that ensures each label is accurately trimmed to size before application.

The machine's precision is further enhanced by its ability to adjust to different product sizes and shapes. This flexibility is achieved through programmable settings that allow operators to customize the labeling process according to specific requirements. For example, the machine can be calibrated to apply labels at different angles, positions, or even on multiple sides of a product.

Benefits of Automatic Flat Labeling Machines

The advantages of using an automatic flat labeling machine are numerous and significant. Firstly, it dramatically increases production speed. Manual labeling is a time-consuming process, prone to errors and inconsistencies. In contrast, an automatic labeling machine can apply labels at a rate of hundreds or even thousands per hour, depending on the model.

Secondly, the machine ensures high labeling accuracy. Each label is applied with precision, reducing the risk of mislabeling or label misplacement. This is particularly important in industries such as pharmaceuticals, where labeling accuracy is critical for regulatory compliance and consumer safety.

Moreover, automatic flat labeling machines contribute to cost savings. By reducing the need for manual labor, companies can allocate resources more efficiently. Additionally, the consistent quality of labeling reduces waste and rework, further enhancing overall operational efficiency.

www.beiltmachinery.com

Shanghai BEILT Machinery Equipment Co., Ltd.