On-site Flange Repair with MT Portable’s FE12 Flange Facing Machine at Guanxing Chemical

In July 2025, MT Portable Machine successfully deployed its advanced FE12 Flange Facing Machine to provide a critical on-site solution for Guanxing Chemical, a leading manufacturer of modified asphalt production equipment and pressure vessels in China. The project highlighted the FE12's outstanding performance and adaptability in the bitumen processing and pressure vessel fabrication industry.

Industry Challenge: Damaged Small-Diameter Flanges

In the manufacturing of bitumen and rubber-modified asphalt systems, pressure vessels and storage tanks often include numerous small-diameter branch flanges. These flanges are frequently subject to handling damage during lifting, transportation, or welding. Even minor nicks or scratches on the flange face can lead to seal failure, resulting in leaks, increased maintenance costs, and potential operational hazards.

Guanxing Chemical had over 100 flanges requiring reconditioning. Traditional repair methods were time-consuming and lacked precision, prompting the client to seek a portable, high-precision solution for in-situ machining.

The Solution: FE12 Flange Facing Machine

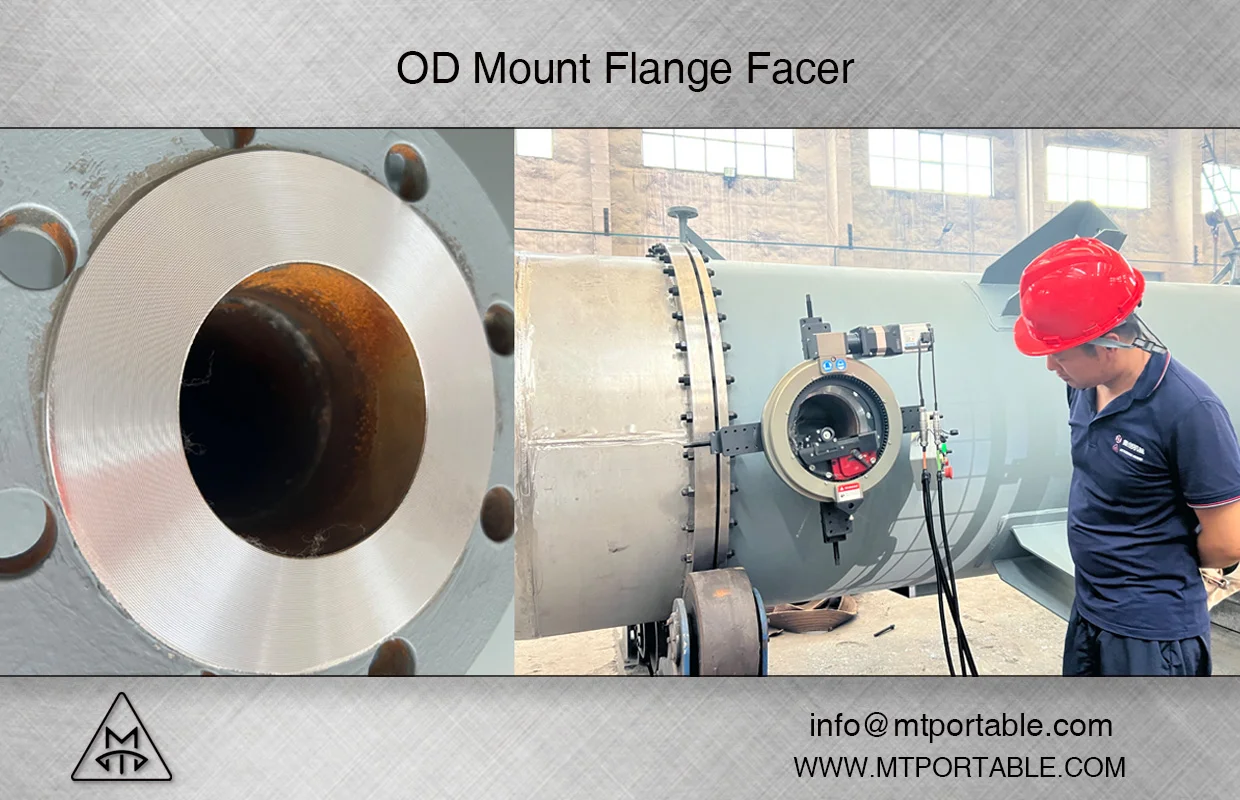

The FE12 Flange Facing Machine, designed and manufactured by MT Portable Machine, proved to be the ideal tool for this application. With its externally mounted, split-frame design, the FE12 could be quickly clamped to the flange OD without the need for time-consuming alignment. Its high-precision bearing system ensured a perfectly smooth, ASME-compliant finish on both flat face and raised face flanges.

The FE12P pneumatic version, featuring a 1.0 kW MT high-torque air motor, was selected for this project due to its suitability for hazardous environments and compact footprint. With two continuous feed settings (0.125 mm/rev and 0.5 mm/rev), the machine delivered the required “gramophone finish” on every flange, restoring sealing surfaces to factory-new condition.

Field Results

Over the course of several days, the MT Portable Machine on-site service team operated the FE12 to recondition over 20 small flanges per 8-hour shift, demonstrating both efficiency and precision. Guanxing’s engineering department praised the rapid setup, minimal clearance requirements, and robust build of the machine. The FE12’s ability to deliver repeatable machining performance across varying flange sizes proved critical to meeting tight production schedules.

The MT Portable Machine field service engineers were commended for their quick response, professional on-site assessment, and the speed at which they executed the repair work. The customer has since integrated the FE12 into their regular maintenance program, citing its role in reducing downtime and enhancing product reliability.

Contact Us for Your On-Site Flange Repair Needs

If your facility is facing challenges with damaged flanges, pressure vessel maintenance, or pipeline equipment repairs, MT Portable Machine has the tools and expertise to help. Our technical team is ready to provide the latest product specifications, application support, and tailored on-site solutions for your machining challenges.

Contact us at info@mtportable.com to learn more about the FE12 and our full line of portable flange facing machines.

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd