Elevator traction systems are the backbone of modern vertical transportation, ensuring smooth, safe, and efficient movement within buildings of all types. Whether for high-rise commercial towers or mid-rise residential complexes, selecting the right elevator traction system is critical for performance, safety, and long-term reliability. For building owners, developers, and elevator system integrators, understanding the key specifications to check when buying elevator traction systems is essential to making an informed investment.

In this article, we will explore the main technical and operational specifications you should consider when selecting elevator traction systems, helping you ensure safety, efficiency, and cost-effectiveness.

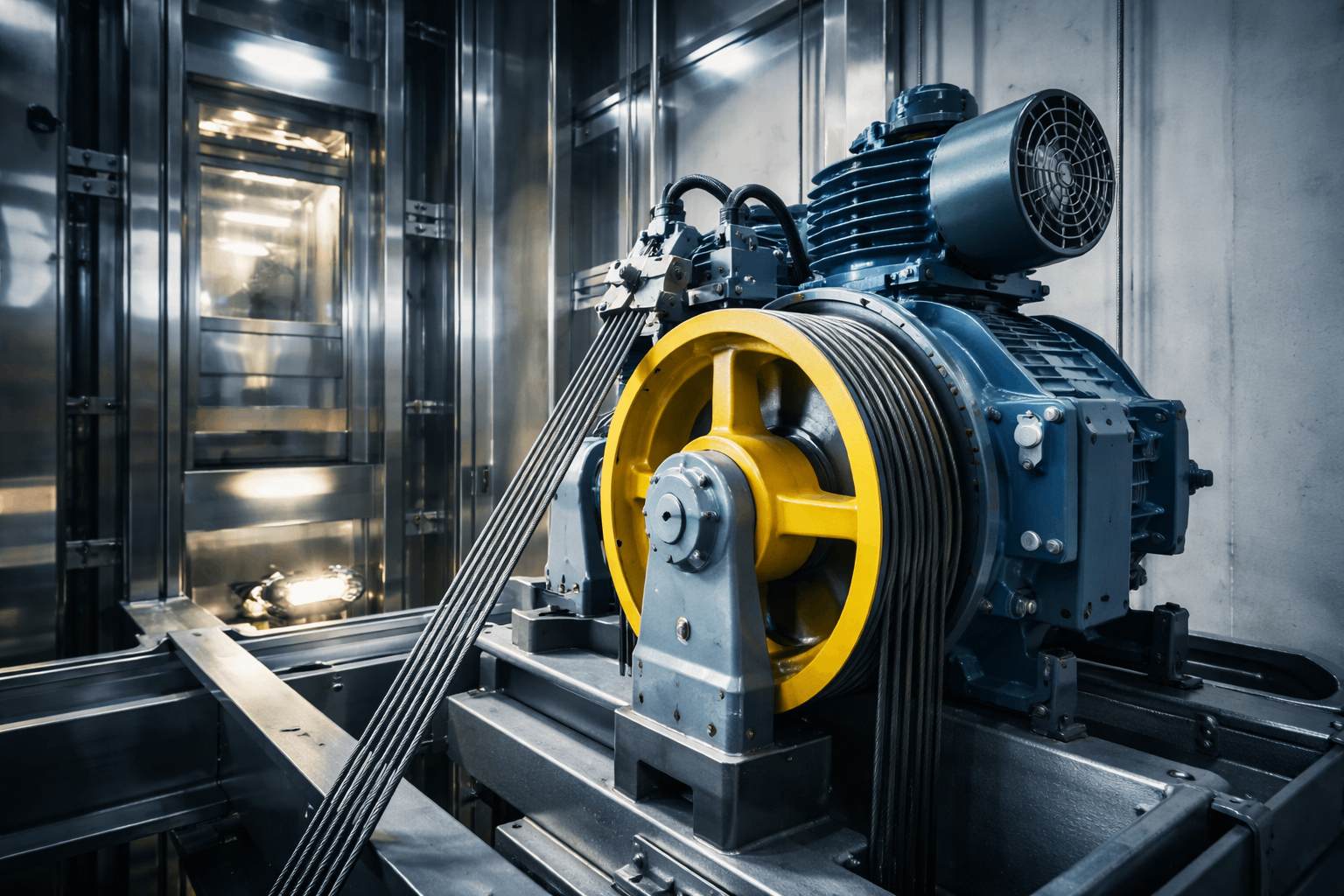

1. Traction Type: Geared vs Gearless

The first and most fundamental specification is the type of traction system. Elevator traction systems are broadly classified into geared and gearless systems:

-

Geared Traction Systems:

These systems feature a gear reduction unit connected to the traction motor, which drives the elevator ropes. Geared systems are typically more suitable for mid-rise buildings (up to 20 floors) due to their moderate speed and lower initial cost. They are robust, reliable, and easier to maintain, making them a popular choice in commercial and residential buildings. -

Gearless Traction Systems:

Gearless systems, in contrast, connect the elevator ropes directly to the motor without a gearbox. This design provides higher speeds and smoother ride quality, making it ideal for high-rise and super-tall buildings. Gearless traction systems are more energy-efficient and require less maintenance than geared systems but involve a higher upfront cost.

When buying an elevator traction system, it is critical to assess your building’s height, passenger traffic, and budget before deciding on the type of traction system.

2. Load Capacity

Load capacity, also referred to as rated load, is a key specification that determines how many passengers or how much weight an elevator can safely carry. Elevator traction systems are designed to handle different capacities, typically ranging from 450 kg to over 2,500 kg for commercial applications.

Consider the following when evaluating load capacity:

-

Passenger Traffic: High-traffic buildings such as airports, shopping malls, or office towers require higher-capacity elevators to reduce waiting times and improve efficiency.

-

Future Expansion: If your building may experience increased traffic in the future, it is wise to choose a traction system with a slightly higher capacity than current needs.

-

Safety Margins: Ensure the system meets or exceeds local elevator safety codes regarding load ratings.

3. Travel Speed

The travel speed of an elevator is directly related to the building’s height and intended usage. Elevator traction systems can operate at a wide range of speeds:

-

Low-rise buildings (up to 10 floors) typically use speeds of 1.0–1.75 m/s.

-

Mid-rise buildings may require speeds of 2.0–3.0 m/s.

-

High-rise and skyscraper elevators often exceed 5.0 m/s, with some ultra-high-speed elevators reaching 10 m/s or more.

High-speed elevators require gearless traction systems with precise motor control to ensure passenger comfort and minimal vibration. Always verify that the system’s maximum travel speed matches your building’s height and operational requirements.

4. Motor Type and Power

The traction motor is the heart of the elevator system. Key specifications to check include:

-

Motor Type: Common options include AC induction motors, permanent magnet synchronous motors (PMSM), and variable-frequency drive (VFD) motors. PMSMs are highly efficient, compact, and ideal for energy-saving applications.

-

Motor Power: Ensure that the motor provides sufficient torque to move the rated load at the required speed, including allowances for peak loads and emergency operations.

-

Energy Efficiency: Modern traction motors often include regenerative braking, which feeds energy back into the building’s grid, reducing overall power consumption.

Selecting the right motor ensures smooth acceleration, deceleration, and energy efficiency while maintaining long-term reliability.

5. Rope Configuration and Diameter

Elevator traction systems rely on steel ropes or flat belts to lift the car. The number of ropes and their diameter directly influence load capacity, speed, and safety.

-

Number of Ropes: More ropes increase safety margins and distribute the load more evenly. High-rise buildings often require multi-rope configurations.

-

Rope Diameter: Thicker ropes provide greater strength but require larger sheaves, which can affect the design of the traction machine.

-

Material Quality: High-quality steel ropes or coated synthetic belts improve durability, reduce wear, and minimize maintenance costs.

Always confirm the manufacturer’s specifications for rope strength, lifespan, and compatibility with your elevator design.

6. Braking System

The braking system is a critical safety component of any elevator traction system. Key specifications to consider include:

-

Type of Brakes: Most traction systems use electromechanical brakes, which are spring-applied and released by motor power. Gearless systems may also use disc brakes for precise control.

-

Redundancy: Ensure that the braking system includes fail-safe mechanisms in case of power loss or mechanical failure.

-

Compliance: The brakes must meet local safety codes and standards, such as EN 81 in Europe or ASME A17.1 in the U.S.

Reliable braking systems are non-negotiable for passenger safety, especially in high-rise installations.

7. Control System and Drive Technology

Modern elevator traction systems are equipped with sophisticated control systems that manage acceleration, deceleration, leveling, and energy efficiency. Important specifications include:

-

Variable-Frequency Drives (VFDs): These drives allow smooth speed changes, reduce mechanical stress, and improve energy efficiency.

-

Destination Control Systems (DCS): For high-rise buildings, DCS optimizes passenger routing, reducing wait and travel times.

-

Monitoring and Diagnostics: Advanced control panels can detect faults early, schedule maintenance, and reduce downtime.

A high-quality control system ensures smooth operation, reduces wear and tear, and improves the overall passenger experience.

8. Compliance with Safety Standards

Elevator traction systems must adhere to national and international safety regulations. When purchasing, confirm that the system complies with:

-

EN 81 (Europe): Safety rules for the construction and installation of elevators.

-

ASME A17.1 (USA): Safety code for elevators and escalators.

-

ISO Standards: Relevant standards for quality management, safety, and performance.

Compliance ensures legal approval for building occupancy and guarantees passenger safety.

9. Maintenance Requirements and Serviceability

Maintenance is a crucial aspect of long-term elevator performance. Key considerations include:

-

Ease of Access: Ensure the traction machine and ropes are accessible for inspections and adjustments.

-

Lubrication Requirements: Some systems require regular lubrication, while modern gearless systems are often maintenance-free.

-

Manufacturer Support: Verify the availability of replacement parts, service agreements, and technical support.

Low-maintenance traction systems reduce operational costs and downtime, providing better ROI for building owners.

10. Noise and Vibration Levels

Passenger comfort is directly influenced by noise and vibration. Gearless traction systems are generally quieter and smoother than geared systems. Important specifications to check include:

-

Decibel Levels: Ensure the system meets acceptable noise standards for residential or commercial environments.

-

Vibration Control: Properly designed traction sheaves and damping mechanisms minimize vibrations.

For premium buildings, low-noise systems enhance the perceived quality and value of the elevator installation.

Conclusion

Selecting the right elevator traction system involves careful evaluation of multiple specifications, from traction type and load capacity to motor type, braking system, control technology, and safety compliance. For high-rise projects, gearless systems with high-speed motors and advanced control panels are often the preferred choice, while mid-rise buildings may benefit from geared systems for cost-effectiveness and simplicity.

By thoroughly checking these key specifications, building owners, developers, and elevator integrators can ensure safe, reliable, and efficient vertical transportation that meets passenger needs, complies with safety standards, and offers long-term operational efficiency.

When buying elevator traction systems, never compromise on safety, performance, or manufacturer reliability. Investing time in evaluating specifications today can save significant costs and prevent operational issues in the future.

www.xinlinelevator.com

xinlinelevator