In the world of manufacturing, high precision plastic injection molds for sale are the unsung heroes that enable the creation of a vast array of plastic products. These molds are the backbone of quality plastic products, ensuring that each item produced is consistent, durable, and meets the highest standards of precision and detail. This blog post will provide an in-depth look at the technical aspects of high precision plastic injection molds, their importance in the manufacturing process, and the factors to consider when purchasing these critical tools for your production line.

Understanding High Precision Plastic Injection Molds

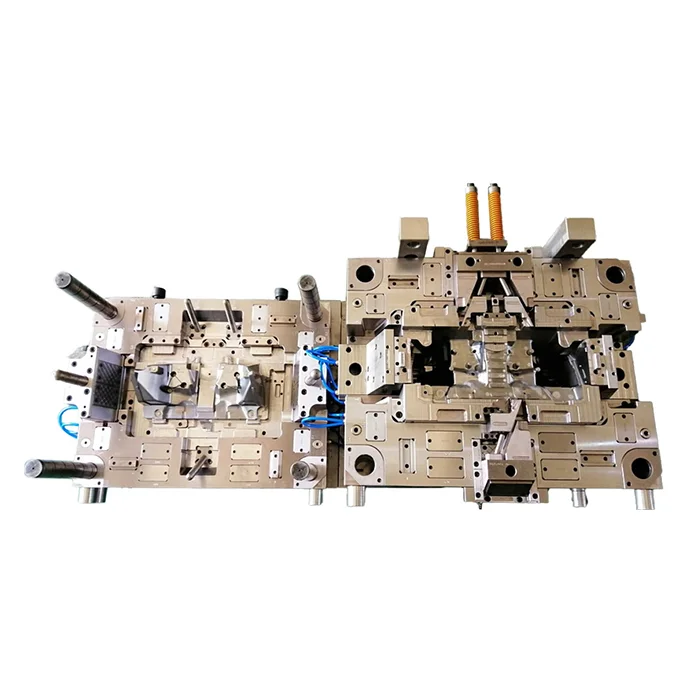

High precision plastic injection molds are the heart of the injection molding process, which is a manufacturing method used to produce plastic parts by injecting molten material into a mold cavity and allowing it to cool and solidify. The precision of the mold directly affects the quality of the final product.

Key Components of High Precision Plastic Injection Molds

Cavity and Core

The cavity and core are the male and female parts of the mold that form the shape of the plastic part. They must be designed with extreme precision to ensure the final product's accuracy.

Gate System

The gate system controls the flow of molten plastic into the mold cavity. It must be designed to minimize material waste and ensure even distribution of the plastic.

Cooling System

A proper cooling system is essential to regulate the temperature of the mold and speed up the cooling process of the plastic, affecting the cycle time and part quality.

Ejection System

The ejection system removes the finished part from the mold. It must be designed to minimize damage to the part and ensure easy and consistent removal.

Materials

High precision molds are typically made from steel, with specific alloys chosen for their strength, wear resistance, and ability to hold tight tolerances.

Technical Specifications of High Precision Plastic Injection Molds

When evaluating high precision plastic injection molds for sale, consider the following technical specifications:

Tolerance level

The tolerance level of the mold determines the allowable deviation from the nominal dimensions of the part. Higher precision molds have tighter tolerances.

Surface Finish

The surface finish of the mold directly affects the appearance and texture of the final product. It is measured in terms of roughness, such as Ra or RMS values.

Temperature Control

Precision molds often have integrated temperature control systems to maintain consistent temperatures throughout the mold, ensuring uniform material cooling and part quality.

Material Compatibility

The mold material must be compatible with the plastic being used to prevent chemical reactions that could affect the part's quality or the mold's longevity.

Cycle Time

The cycle time is the time it takes to produce one part. High precision molds are designed to minimize cycle time while maintaining part quality.

Durability

The mold must be durable enough to withstand thousands or even millions of cycles without significant wear or damage.

The Role of High Precision Plastic Injection Molds in Manufacturing

High precision plastic injection molds for sale are essential for manufacturers for several reasons:

Consistency

Precision molds ensure that every part produced is identical, which is critical for assembly, function, and aesthetic consistency.

Quality

The precision of the mold directly affects the quality of the final product, including dimensional accuracy, surface finish, and overall durability.

Efficiency

High precision molds can lead to reduced waste and increased production efficiency, as fewer parts will be rejected due to defects.

Cost Savings

While high precision molds may have a higher upfront cost, they can save money in the long run by reducing material waste, rework, and scrap.

Customization

Precision molds enable the production of complex, customized parts that may not be possible with lower precision molds or other manufacturing methods.

Market Factors Affecting the High Precision Plastic Injection Molds for Sale Industry

Several market factors influence the high precision plastic injection molds for sale industry:

Technological Advancements

Advancements in materials, design software, and manufacturing technologies are driving the development of more precise and efficient molds.

Global Competition

The industry is global, with competition from manufacturers around the world. This competition drives innovation and can affect pricing.

Regulatory Environment

Regulations related to product safety, environmental impact, and material restrictions can affect the design and production of molds.

Economic Conditions

Economic downturns can reduce demand for new molds, while upturns can increase demand as companies invest in new production capabilities.

Sustainability

There is a growing focus on sustainable manufacturing practices, which can influence the materials and processes used in mold production.

Challenges Faced by High Precision Plastic Injection Mold Providers

Providers of high precision plastic injection molds for sale face several challenges:

Maintaining Precision

Maintaining the highest levels of precision in mold design and manufacturing is a constant challenge, requiring state-of-the-art equipment and skilled technicians.

Meeting Customer Expectations

Customers have high expectations for the quality and performance of molds, which providers must meet to maintain their reputation and customer base.

Staying Competitive

Providers must continuously invest in research and development to stay ahead of competitors and offer the latest technologies and innovations.

Managing Supply Chain

The complexity of global supply chains can lead to delays and increased costs, which providers must manage effectively.

Adapting to Market Changes

Providers must be agile and adaptable to changes in the market, such as shifts in demand or the emergence of new technologies.

Future Trends in the High Precision Plastic Injection Molds for Sale Industry

The industry is poised for several significant trends:

Digitalization

The use of digital technologies, such as 3D printing and simulation software, will continue to grow, enabling faster prototyping and more precise mold design.

Material Innovations

New materials with improved properties, such as better wear resistance or thermal conductivity, will be developed to enhance mold performance.

Sustainability

There will be a continued push towards more sustainable manufacturing practices, including the use of recycled materials and energy-efficient production processes.

Customization

The demand for customized parts will drive the development of more flexible and adaptable mold designs that can quickly change to produce different parts.

Automation

Increased automation in mold manufacturing will lead to higher precision, improved efficiency, and reduced labor costs.

Conclusion

High precision plastic injection molds for sale are the backbone of quality plastic products, enabling manufacturers to produce parts with consistency, efficiency, and precision. As the industry evolves, providers must navigate changing market dynamics, technological advancements, and sustainability concerns to deliver the high-quality molds that their customers demand. By understanding the technical aspects and market trends, providers can stay ahead in this competitive industry and continue to offer the high precision plastic injection molds that are essential for producing the plastic products we rely on every day.

https://www.xuzhongmold.com/high-precision-plastic-injection-mold.html

www.xuzhongmold.com

Xuzhong