In laboratories, semiconductor facilities, and other precision industries, maintaining a contamination-free environment is essential. A Class 100 Clean Bench is a key piece of equipment designed to provide a controlled workspace where airborne particles, dust, and microbes are minimized, ensuring the safety and integrity of experiments, processes, and products. For high-quality solutions in laboratory and industrial plastic equipment, companies like Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. offer advanced clean benches, tailored to the rigorous standards of modern scientific and industrial applications.

What Is a Class 100 Clean Bench?

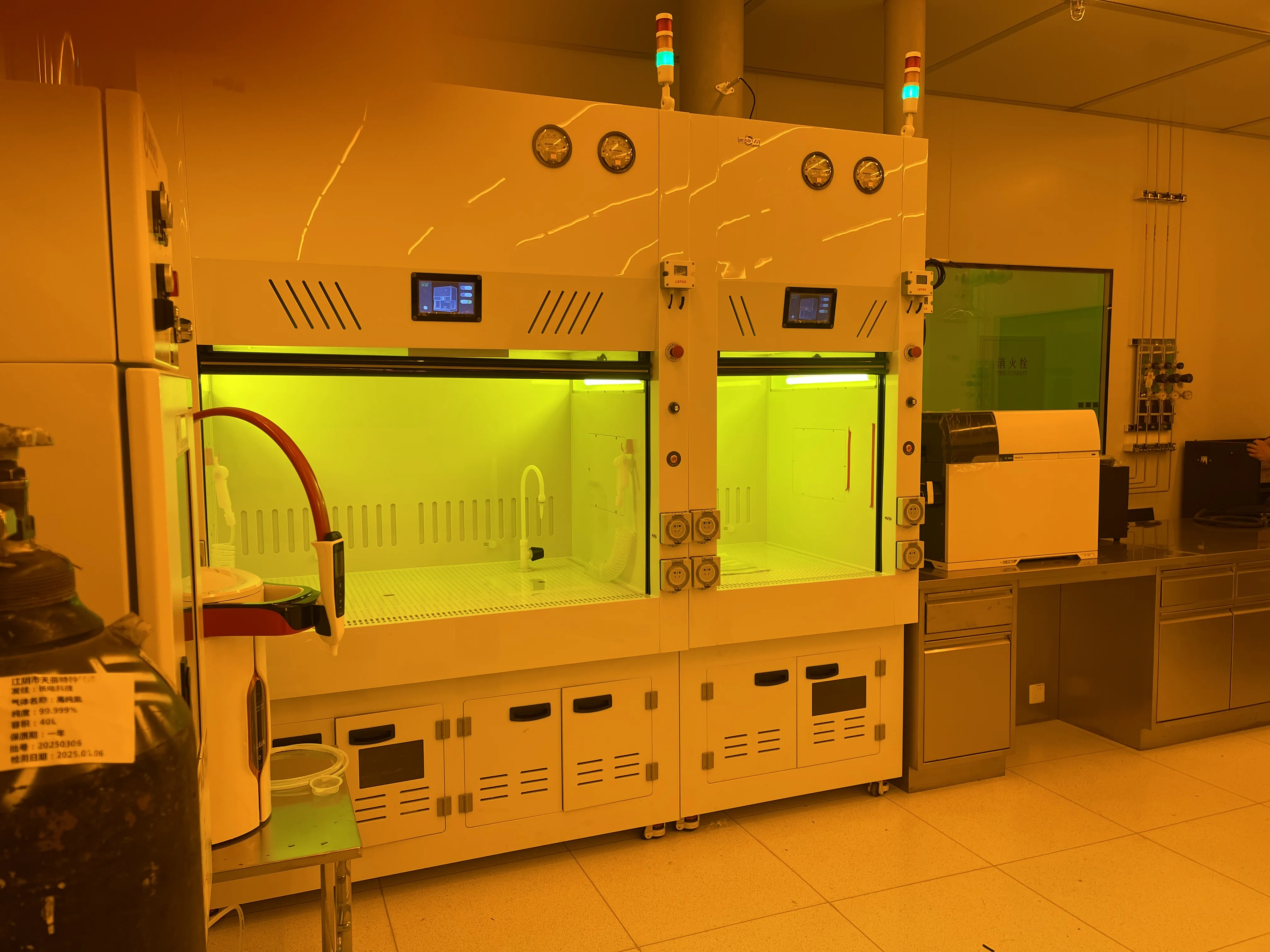

A Class 100 Clean Bench, also known as a laminar flow workstation, is a specialized workbench that delivers a sterile and particle-free environment. The term “Class 100” refers to the maximum allowable particle count of 100 particles per cubic foot of air at 0.5 microns, according to the Federal Standard 209E classification system. This high level of cleanliness makes it suitable for applications requiring extreme precision and sterility.

The clean bench operates by drawing ambient air through HEPA filters and projecting it as a laminar flow over the work surface. This unidirectional airflow prevents external contaminants from entering the workspace, safeguarding sensitive materials and experiments.

Key Features of a Class 100 Clean Bench

-

High-Efficiency Particulate Air (HEPA) Filtration

HEPA filters are the core of the clean bench, capable of removing 99.97% of airborne particles ≥0.3 microns. This ensures a highly purified workspace essential for laboratories, semiconductor manufacturing, and pharmaceutical applications. -

Laminar Airflow Design

A unidirectional, laminar airflow minimizes turbulence and keeps particles from settling on sensitive samples or components. This design ensures consistent sterility across the entire work surface. -

Durable Construction

Modern clean benches are typically made from corrosion-resistant stainless steel or specialized plastics. Xinruiwei Semiconductor Technology specializes in laboratory and industrial plastic equipment, delivering clean benches with robust, high-quality materials, incorporating European components for reliability and precision. -

Ergonomic and User-Friendly Design

Clean benches often feature adjustable work surfaces, easy-to-replace filters, and convenient controls, providing a safe and efficient workspace for laboratory staff and technicians.

Applications of Class 100 Clean Benches

Class 100 Clean Benches are widely used in industries and laboratories where contamination control is critical:

-

Semiconductor Manufacturing: Protects delicate wafers and electronic components from dust and particulate contamination.

-

Pharmaceutical and Biotechnology Labs: Ensures sterile handling of chemicals, reagents, and biological samples.

-

Medical Device Production: Prevents contamination in the assembly of sensitive devices.

-

Research Laboratories: Provides a controlled environment for experiments, tissue culture, and chemical analysis.

Xinruiwei Semiconductor Technology supports these applications by offering customized solutions, from prototypes to full-scale production units, tailored to meet the specific requirements of labs and industrial operations.

Benefits of Using a Class 100 Clean Bench

-

Enhanced Contamination Control

By maintaining a Class 100 environment, clean benches prevent dust, microbes, and other particles from compromising experiments or products, improving overall yield and reliability. -

Compliance with Industry Standards

Using a Class 100 Clean Bench helps facilities meet regulatory requirements in pharmaceuticals, electronics, and biotechnology, ensuring operational compliance and product safety. -

Improved Productivity

A clean, controlled workspace reduces the risk of contamination-related errors and rework, increasing efficiency and workflow reliability. -

Long-Term Cost Savings

While clean benches require an initial investment, their ability to prevent contamination and product loss can significantly reduce long-term costs associated with damaged materials or failed experiments.

Why Choose Xinruiwei Semiconductor Technology

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. is a leading developer and manufacturer of laboratory and industrial plastic equipment. Their clean benches integrate:

-

High-quality European components for precision and reliability

-

Customizable designs for specific lab or production needs

-

Expertise in both prototyping and large-scale production

-

Robust manufacturing in China with strict quality control and reliable delivery

By leveraging Xinruiwei’s solutions, laboratories and industrial facilities can ensure that their Class 100 clean benches provide both superior performance and long-term reliability.

Conclusion

A Class 100 Clean Bench is indispensable for environments that require strict contamination control, offering a sterile workspace for sensitive experiments and production processes. With features such as HEPA filtration, laminar airflow, and durable construction, clean benches help maintain product quality, safety, and compliance.

Partnering with Xinruiwei Semiconductor Technology ensures that your clean bench solution meets the highest standards of precision, durability, and customization, making it an ideal choice for laboratories, semiconductor facilities, and industrial applications. Investing in a Class 100 clean bench not only enhances operational efficiency but also protects critical materials and processes, delivering both reliability and peace of mind.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.